I hope you enjoy reading this blog post.

If you are looking professional golf manufacturer.

How Are Golf Balls Made?

May 7, 2024

How Is The Core Of A Golf Ball Made

The core of a golf ball is typically made of a solid or liquid-filled center designed to provide the ball with its initial velocity and energy transfer upon impact with the clubface.

The construction of the core can vary depending on the type of golf ball and the desired performance characteristics.

For traditional two-piece golf balls, the core is usually made of a high-energy rubber compound or a mixture of synthetic materials. These materials are molded into a solid core that provides the ball with its density and compression.

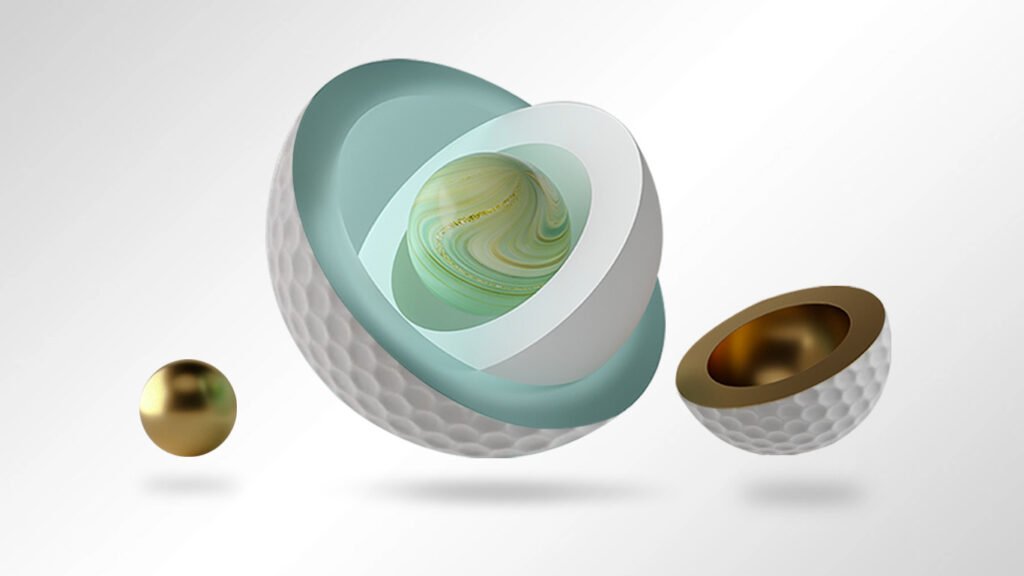

In multi-layer golf balls, the core may consist of multiple layers, each with its own properties and materials.

For example, some multi-layer balls have a soft inner core surrounded by firmer outer layers. This construction is designed to optimize spin, distance, and feel.

In premium golf balls, the core may also incorporate advanced technologies such as gradient density or dual-core designs. These innovations aim to enhance performance by optimizing energy transfer and reducing spin for longer, straighter shots.

How Is The Outer Layer Of A Golf Ball Made

The outer layer of a golf ball, often referred to as the cover, is responsible for providing durability, spin control, and feel. The cover material and construction play a significant role in the performance of the ball.

Here’s an overview of how the outer layer of a golf ball is typically made:

Cover Material: Golf ball covers are commonly made of either ionomer, urethane, or a blend of these materials.

- Ionomer: Ionomer covers are typically found on two-piece golf balls and some lower-priced multi-layer balls. They offer durability and distance but may not provide as much spin control or feel as urethane covers.

- Urethane: Urethane covers are often found on premium golf balls. They offer excellent spin control, feel, and responsiveness, particularly on approach shots and around the green. Urethane covers are softer than ionomer covers, allowing for more precise shot-making.

- Cover Construction: The cover material is molded or cast onto the core of the golf ball during manufacturing. The process may involve compression molding, injection molding, or casting, depending on the type of cover material and the desired characteristics of the ball.

- Dimple Pattern: Once the cover is applied, dimples are then added to the surface of the ball. Dimples are critical for aerodynamics, helping to reduce drag and optimize lift during flight. The pattern, size, and depth of dimples can vary depending on the specific design goals of the golf ball.

- Additional Layers (Optional): Some multi-layer golf balls may feature additional layers between the core and the cover, such as mantle layers or intermediate layers. These layers can further enhance performance by fine-tuning spin, feel, and trajectory.

Overall, the outer layer of a golf ball is carefully engineered to balance durability, spin control, and feel, allowing golfers to achieve optimal performance across a variety of shots and playing conditions.

FAQS

How are golf balls molded?

The materials are heated and molded under pressure to form the core and layers, then assembled and covered.

How are the dimples created?

Dimples are molded into the cover during manufacturing, affecting aerodynamics and flight stability.

Why do different balls perform differently?

Variations in materials, construction, and dimple patterns influence distance, spin, and control, catering to different player preferences.

Are there environmentally friendly golf balls?

Yes, some manufacturers are producing eco-friendly balls using biodegradable materials.

How long does it take to make a golf ball?

The entire manufacturing process can take several hours, but it depends on the complexity and number of layers involved.

Leave a Reply

Your email address will not be published. Required fields are marked *